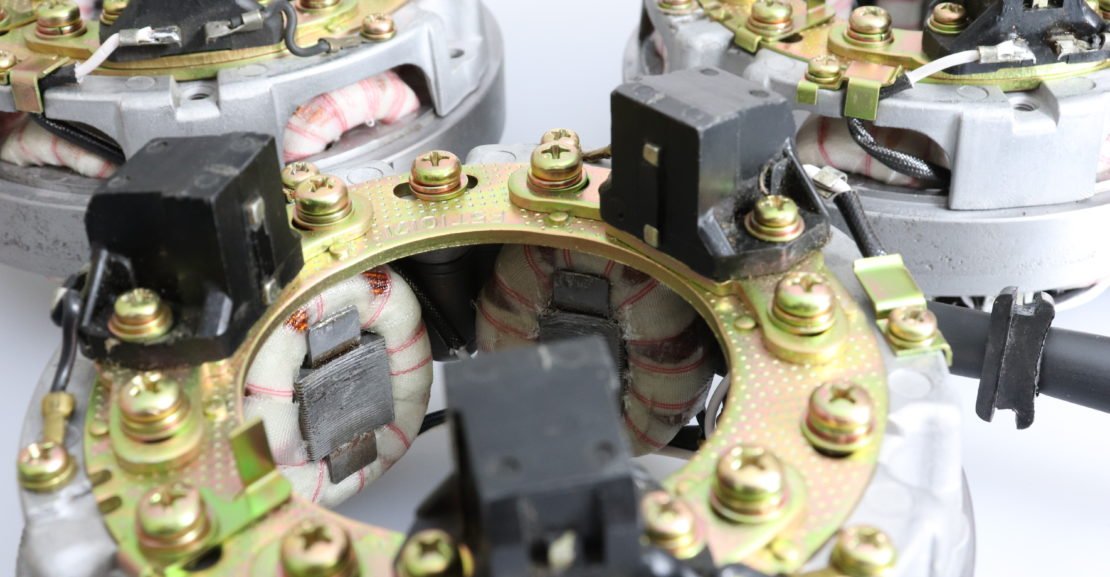

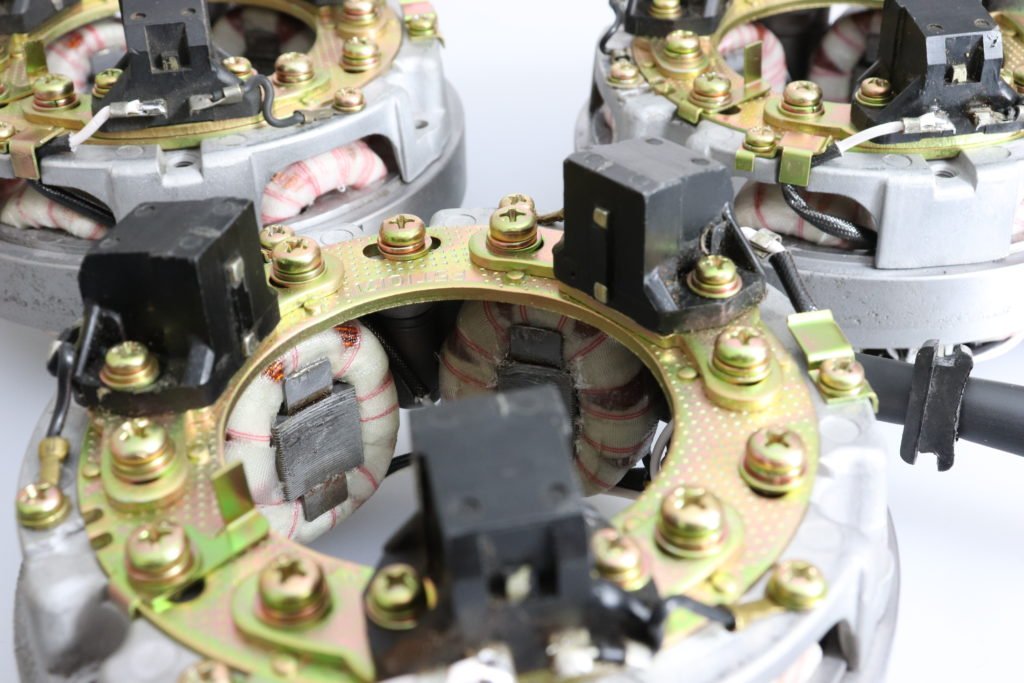

Our workshops have seen nearly every generator type fitted to the iconic Kawasaki triple models sent in to for repair, rewind or restoration. The past few weeks have been extremely busy with some sent to us that we’d not seen before. We made brand new tooling in order to re-create the windings to allow us to repair these too. Other alternators where even more challenging, accident damaged units that we were able to save by building one good assembly from a collection of failed parts. From KH250s, KH400, H1 500s and the H2 750s we are able to return them to as new or better.

The process is simple, first we inspect units sent to us then give the customer a report and pricing options. The owner of the parts in the picture wanted them restored to ‘as new.’ First all the old wires are removed and the metal work blast cleaned, meanwhile the yellow zinc parts are sent for replating. We out-source this as professional plating is vastly better than attempting this with DIY kits. We include new hardware and fasteners so these come back with the correct finish as well. Once all the metal parts are clean and re-plated the generator is re-assembled with brand new machine wound coils.

The windings are subjected to a VPI process to ensure they are resilient to engine vibration. Once the resin has set new leads are added and the unit is checked for resistance and insulation strength. The restored unit comes with a one year warranty.